The Ardent Mills 2022-23 Guide to Flour Treatments

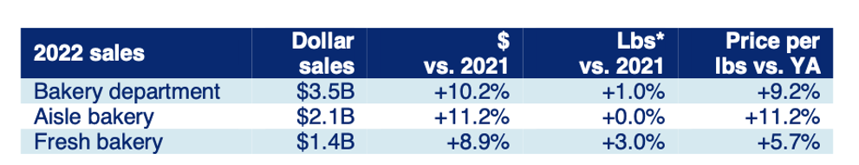

Consumer demand for baked goods has increased year-over-year, driving dollar sales growth across the bakery department (+10.2%), aisle bakery (+11.2%), and fresh bakery (+8.9%).

This uptick in sales and volume has a lot to do with consumers eating out less during the COVID-19 pandemic, but it is also strongly tethered to an increased consumer prioritization of consistency, quality, and perceived “cleaner” ingredients.

For established and emerging consumer packaged goods (CPG) brands with products coming to the shelf in the bakery aisle, achieving these product attributes is more complex than it may appear. Flour type and quality have a major impact on the end product. For example, a low-protein, low-gluten flour is best for the lightest and airiest cakes and pastries, but a high-protein, high-gluten flour is best for dense and crusty breads.

Further, in the ever-expanding push toward perceived “cleaner” nutrition labels, many artisan bakers and foodservice professionals are making the move to unbleached and unbromated flour—the switch results in minimal impact on dough or crust yet comes with a large corresponding consumer payoff.

Regardless of the product a brand wants to create, flour treatment—the process of using additives to improve the baking quality or color of flour or dough—remains an essential piece of delivering the same high-quality experience for every product in your portfolio.1

In the face of high shelf competition, supply chain issues, and the ever-present risk of recall, established and emerging CPG brands alike don’t have any room for error when it comes to quality or consumer safety. Flour treatments are a key way to help manage quality. They can even reduce microbial risk when they include Ardent Mills Safeguard®.

Here’s a comprehensive look at five flour treatments that may be utilized to ensure the best appearance, accelerate aging and maturation, or maintain safety across your product portfolio.

Bleaching for color and quality

In the bleaching process, a bleaching agent like benzoyl peroxide is added to remove the natural creamy yellow color of flour and produce a whiter flour. Bleaching may also be achieved by adding chlorine gas to flour. In cake flour, adding chlorine results in improved volume and a finer crumb texture, as well as a reduction of flour pH. Chlorine can also be added in lesser amounts to cookie flour in order to control cookie spread during baking .

It’s interesting to note that unbleached flour doesn’t function differently from bleached flour; the change is purely aesthetic. In fact, it is appealing to a segment of consumers who prefer untreated ingredients. For example, CPG brands enjoy Ardent Mills Hungarian® High Altitude® Flours—all-purpose, whole wheat, and unbleached—for similar product applications in biscuits, cookies, muffins, and quick breads.

Maturing for texture

The maturing process involves adding agents like potassium bromate2 and ascorbic acid3 in flour for pizza, bagel, and bread doughs. It strengthens the flour’s dough-forming ability, improving gas retention of the “sticky” gluten within the flour and letting the product achieve a higher crust, finer grain, and chewier texture.

Malting for flavor4

During the malting process, enzymes are added to supplement naturally occurring wheat enzymes. These enzymes convert starch into fermentable sugars, then yeast converts the sugars into carbon dioxide and alcohol during the fermentation process.

The resulting malted flour creates a more relaxed dough, which shortens mix times and adds browning characteristics that customers love. Explore Ardent Mills Malted Barley Flour.

Enrichment for nutrition

The process of enriching flour involves adding nutrients like B vitamins, iron, and folic acid to refined flour. The process has no effect on the flour’s baking performance, but it allows CPGs and manufacturers to give a nutritional boost to delicious, familiar products like frozen pizza and bakery aisle pastries.

Heat for safety

Flour-related recalls continue to keep CPG manufacturers and emerging CPGs on high alert for safe methods of preparing products for today’s customers. Heat treatment is a process that heats flour to a safe point to reduce the levels of microbes in a product. This can be accomplished with solutions like Ardent Mills SafeGuard®. Heat is the only treatment from this list that addresses microbial safety of flour. It is one of the more expensive treatments for flour, but SafeGuard® is worth the investment for CPGs that want to proactively minimize the risk of pathogens and help protect consumers, especially in the case of raw flour products like edible cookie dough.

Quality, taste, and appearance always win in the long run

Consumer demand for baked goods is higher than ever—and so is the competition. In a landscape that’s becoming cluttered, stand out with flours and baked goods that check the boxes consumers care about the most: taste, quality, and appearance. Creating the right strategy starts with a supply partner that knows what flours work best for your applications and ends with a targeted (and oftentimes custom) flour treatment plan.

Fill out the contact form below, or give us a call so we can review your application’s unique specifications and get to work designing a custom flour treatment plan that your organization (and your customers) will love.

Let’s Continue the Conversation

1Irrespective of the flour treatment(s) referenced above, Ardent Mills reminds all organizations of the critical need to follow generally accepted kill step baking procedures to assist in the elimination of food safety concerns.

2https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.730

3https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.3013

4https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=137.105

Back to all News

Back to all News